Today, heavy-duty rack systems find applications in various settings, including warehouses, industrial facilities, retail stores, commercial spaces, and even residential environments.

The need for durable and efficient storage options cannot be overstated, and heavy-duty racks have emerged as a go-to solution. They provide the versatility and capacity to handle substantial loads while offering efficient space utilisation and easy accessibility.

Different Types of Heavy-Duty Rack

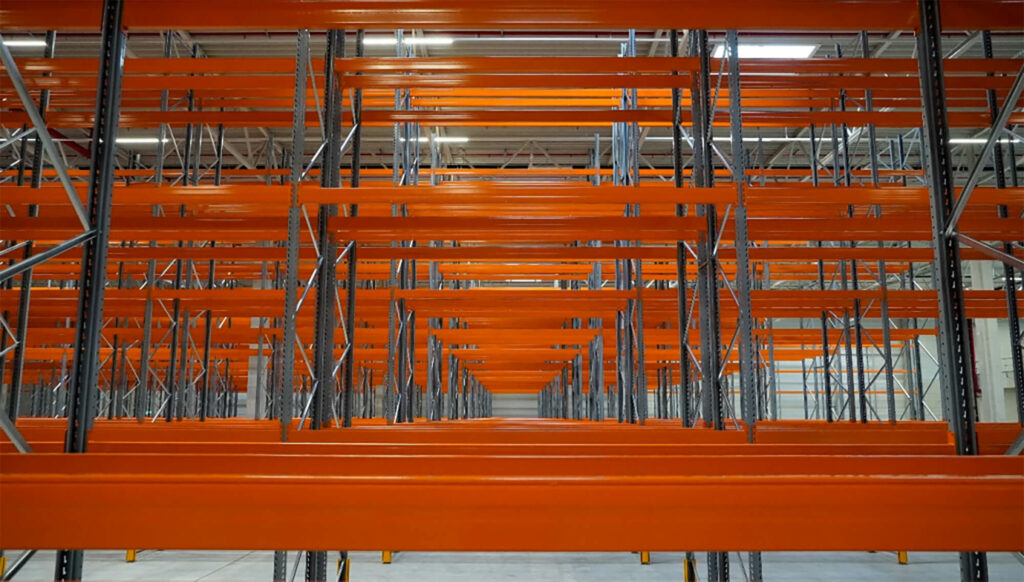

Selective Pallet Racking

Selective pallet racking is one of the most common types of heavy-duty racks. It is designed to store palletised materials in horizontal rows with multiple levels, increasing storage capacity and organisation, as well as providing easy access to stored items. Also, it offers the utmost versatility and flexibility for various storage requirements.

Additionally, you can easily adjust, expand, or reconfigure pallet racking systems to accommodate changing storage needs and inventory profiles. They also enhance warehouse safety by incorporating safety features to promote better work safety and prevention.

Drive-In and Drive-Through Racking

Drive-in and drive-through racking allow forklifts to drive directly into a stacked row, also known as a bay, for high-density storage. They are particularly suitable for storing large quantities of homogeneous products with a low turnover rate.

Moreover, drive-in racking systems can be designed with single or double access to the rack structure. It is important to note that both racking systems require a skilful forklift driver and an in-rack guide to ensure safe operations.

Push-Back Racking

Push-back racking systems use a series of nested carts or rollers together with a whole racking depth. Pallet loads are loaded from the front aisle onto the nested carts or rollers. Operating on the Last-In, First-Out (LIFO) principle, each new load pushes the previous one deeper into the rack.

As a high-density system, push-back racking suits industries with larger quantities of fewer product stock-keeping units (SKUs), such as food and beverage, manufacturing, and general warehousing.

Cantilever Racking

Meanwhile, cantilever racking is ideal for storing long, bulky items like lumber, pipes, or even furniture. This type of racking features horizontal ‘arms’ that extend from a metal framework, supporting the materials stored on them.

Cantilever racking systems are adjustable to accommodate different load sizes and heights. With their high weight capacity and equal weight distribution, they are commonly used to store wide, long, bulky, or irregularly shaped items.

Double-Deep Racking

An extension of pallet racking, double-deep racking involves storing pallets two deep in each aisle. As such, this particular racking system effectively doubles the storage capacity compared to traditional selective racking.

A double-deep racking system requires a special forklift to place pallets on the rear of the rack and provides medium- to high-density storage. It’s a reliable storage solution for warehouses or distribution centres with a high volume of inventory.

Applications of Heavy-Duty Racks

Warehouses and Industrial Settings

Heavy-duty racks are prevalent in warehouses and industrial facilities for efficient storage of large, heavy, or bulky items.

These racks provide robust support and can handle high load capacities, making them suitable for storing items such as machinery, equipment, automotive parts, construction materials, and raw materials.

Above all, they are crucial in enhancing organisation, maximising storage capacity, and ensuring easy access to stored items.

Retail and Commercial Settings

Heavy-duty racks are commonly used for display and storage in retail and commercial settings.

These racks allow for organised and accessible showcasing of products, making it easier for customers to browse and select items.

Retailers often utilise heavy-duty racks for storing goods in backrooms, warehouses, or distribution centres to ensure efficient inventory management and restocking.

Tailored Storage Solutions

Heavy-duty racks are engineered to accommodate and adapt to specific industrial needs.

They offer adjustable configurations, varying load capacities, and specialised components to store materials, products, and equipment of different sizes and weights.

By providing customised storage configurations, these racks provide a systematic way to store items, ensuring optimised space utilisation, accessibility, and safety.

Benefits of Using a Heavy-Duty Rack

Durability

One of the primary advantages of heavy-duty racks is their exceptional durability and robustness.

These racks can withstand heavy loads and endure rigorous usage over time. Manufacturers construct them using high-quality materials, ensuring the strength and stability required to support heavy items.

The durable nature of heavy-duty racks reduces the risk of damage or collapse, providing a reliable storage solution.

Space Efficiency

As they are designed to maximise vertical space utilisation, heavy-duty racks offer excellent space efficiency compared to other storage solutions.

By utilising the height of the storage area, heavy-duty racks enable efficient stacking of goods, effectively multiplying the available storage capacity.

This vertical storage approach helps optimise the overall floor space in warehouses, industrial facilities, retail stores, and even residential storage areas.

Versatility

Heavy-duty racks are designed to accommodate various sizes, shapes, and weights, making them suitable for a wide array of products.

Heavy-duty racks can effectively store items such as large machinery, equipment, bulk goods, pallets, construction materials, retail inventory, and even personal belongings.

This versatility makes heavy-duty racks a valuable storage solution across different industries and environments.

Key Features to Consider When Choosing a Heavy-Duty Rack

Material Quality

Look for racks made from high-quality metals, such as high-tensile steel, that offer excellent durability and strength.

The rack should be able to withstand heavy loads without bending or warping, ensuring both functionality and safety.

Next, choose a rack with a high load-bearing capacity so it can safely support the weight of your stored items.

Designed Loading Capacity

Assess the maximum weight that the rack can safely hold to ensure it can handle the heaviest items you plan to store.

Understanding the loading capacity of a heavy-duty rack is essential, as overloading a rack can compromise its structural integrity and pose safety risks.

Select a rack with a weight capacity that matches your specific storage needs to ensure safe and secure storage.

Rack Dimensions and Layout Organisation

One has to carefully consider the height, width, and depth of the racking system, as well as how it will be laid out in the designated area for long-term sustainable usage.

It is best to choose racks that offer adjustability, such as adjustable shelves or modular components.

This allows you to customise the rack to accommodate different-sized items and adapt to changing storage requirements over time.

Ease of Assembly and Disassembly

Opt for a heavy-duty rack that is easy to assemble and disassemble for utmost convenience and mobility.

Look for racks with clear instructions and minimal assembly tools to simplify the setup process and reduce the time and effort required.

This is critical if you need to relocate or reconfigure the racks in the future, as it enables adaptability in adjusting the storage setup to changing requirements.

Best Practices for Maintaining a Heavy-Duty Rack

Proper Load Distribution

Ensure that you distribute the load evenly across the heavy-duty rack and avoid placing excessive weight on one side or overloading individual shelves.

Uneven weight distribution can lead to structural strain and potential collapse. Thus, arrange items in a balanced manner to maintain the rack’s structural integrity.

Regular Inspections

Regularly inspect the heavy-duty rack for any signs of wear and tear, damage, or potential issues.

Check for bent or damaged components, loose connections, rust, or corrosion. Inspect the rack’s anchoring system, uprights, beams, and other parts.

Early detection of any problems allows for timely repairs or replacements, ensuring the safety and reliability of the rack.

Proper Use and Care

Avoid using the rack by exceeding its weight capacity or using it as a makeshift work surface. Also, do not drop or slam items onto the rack as it may result in permanent structural damage to the racks.

Lastly, don’t forget to follow proper safety protocols when operating any equipment near the rack to prevent accidental damage, such as knocking.

Durable Heavy-Duty Racks for Your Storage Needs

In conclusion, heavy-duty racks provide durable and efficient storage solutions for various industries and environments. With their superior durability, they can withstand heavy loads and endure rigorous usage, ensuring long-term reliability.

At Prestar Storage, we offer efficient heavy-duty racks, including very narrow aisle (VNA) racking systems, structural steel platforms, multi-tier racking systems, and more, to optimise storage space and streamline operations.